Belt dryer is continuous dryer for large production. It is used for drying sheet materials, bar masterials granules materials that have good air permeability. As to dehydrated vegetable Chinese herb pieces which have high moisture and need low drying temperature, DWT belt dryer is specially suitable.

Working principle

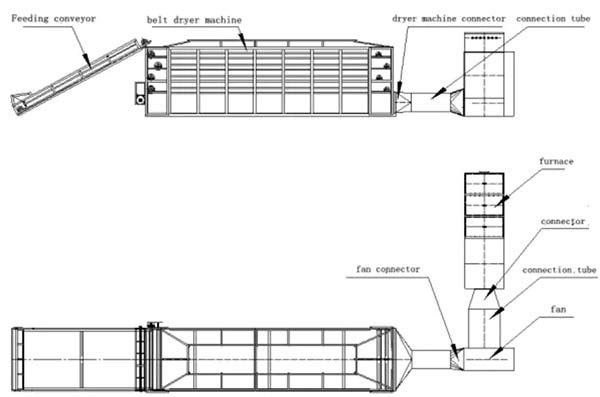

Mesh belt type drying machine main principle is the material evenly tiled on the mesh belt, is driven by the drive device in the dryer moving back and forth, hot air in materials and the cross flow, water vapour from the wet discharging hole in discharge, so as to achieve the purpose of drying. Network with 12-60 to wire mesh belt, the body length by a combination of the standard section, in order to save space, the drying mechanism into multi-layer, common has two room three and two-room five layers, length 6-40m, effective width 0.6-3.0m.

The material has the nose to enter slowly through the drying for drying, net belt line speed depending on the type of material and water content. Air flow to the use of negative pressure, porous air, to ensure the effective drying area, wind speed distribution uniformity, improve the drying effect. In order to get the best drying effect and the appropriate output, the water content of the material, the line speed of the net belt, the air volume and the air temperature must be the appropriate, reasonable and organic combination.

Application

Platy, strip and bulk material.

Especially it is suitable for drying raw materials that are good in breathability and have the shape of pieces or strip of granule. It is also possible to dry the pasted raw materials such as filter cake after shaped through granulator or extruder. In briquette making process, the belt dryer is normally used to drying the final briquette.

Advantage

- There is adopt multilayer structure,and large area of drying,it can continuous produce in large quantities.

- Fully antomatic feeding and discharging.

- The air that combustion chamber and went into the oven is separate,it is clean and health.

- Flexiable fuel choices, such as biomass pellet,natural gas,coal,etc.

Belt

Mesh size between 12-60 mesh, with the stainless steel or other non-metallic materials. The thickness of material on the belt normally between 20-100mm.

Mesh belt dryer is mainly used for drying finished briquette to meet a low moisture for transportation or using, also it has other wild usages for all kinds of material.

Details show

access door

access door chain

chain mesh belt

mesh belt equipped mesh belt

equipped mesh beltHeat source

The main heating mode is electric heating, steam heating, hot air heating,

Characteristic:

1. small investment, fast drying, high evaporation intensity.

2.High efficiency, high output, good quality products.

3.standardized production, according to the number of output increase.

4, adjust the air quantity, heating temperature, material residence time and feeding speed to get the best drying effect.

5, equipment configuration is flexible, can be used in the network with flushing system and material cooling system.

6, most of the air circulation, high energy saving.

7, the unique sub – wind device, so that the hot air distribution more uniform, to ensure the consistency of product quality.

8, the heat source can be steam, heat conduction oil, or gas stove.

Parameter

| Model | YKBD6 | YKBD8 | YKBD10 | YKBD12 | YKBD16 | YKBD20 | YKBD24 | YKBD30 |

|---|---|---|---|---|---|---|---|---|

| Belt width (mm) | 600 | 800 | 1000 | 1200 | 1600 | 2000 | 2400 | 3000 |

| Feeding section length (m) | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 2 |

| Drying area (m²) | 3.6-36 | 4.8-48 | 6-80 | 7.2-96 | 12.8-105.6 | 20-260 | 28.8-360 | 36-600 |

| Layer number | 1-5 | |||||||

| Interlamellar spacing (mm) | 400-600 | |||||||

| Loading capacity (kg/m²) | 90-200 | |||||||

| Operation temperature (°C) | carbon steel ≤ 400 C° stainless steel ≤ 600 C° |

|||||||

| Evaporation intensity (kg/m²·h) | 5-20 | |||||||

| Heat source | hot air, electric, steam, etc. | |||||||

| Running speed (m/min) | 0.06-1 | |||||||

| Accessories | conveyor, air heater, dust collector, draft fan, etc. | |||||||

Remarks: Technical parameter is adjustable for different materials, capacities and moisture.